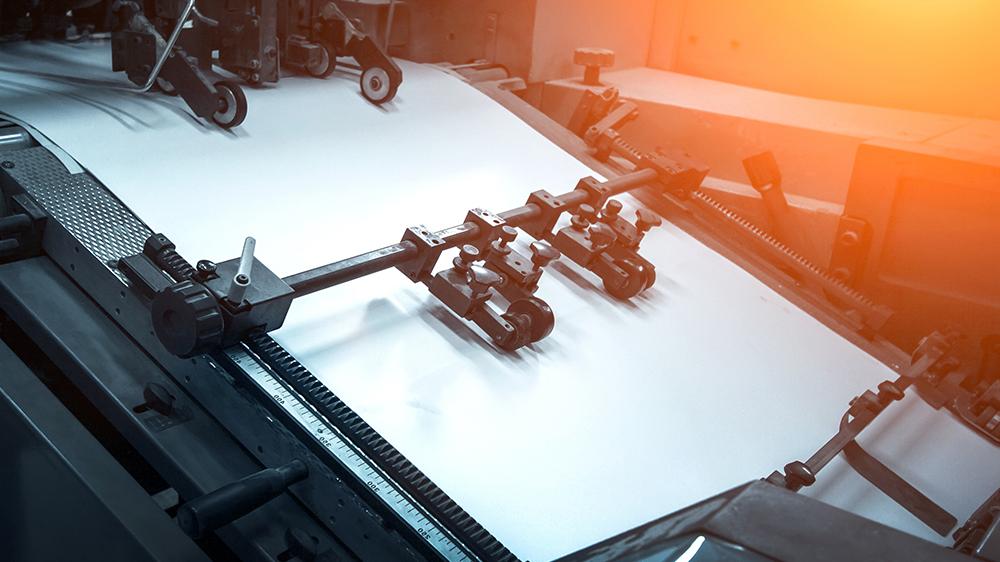

Complex paper-tray control would become a thing of the past. Instead of "x" number of different missives painstakingly assigned to specific trays, there are just infinite rolls of white paper for printing every document: policies, invoices, letters, GTCs, warnings, payment instructions – literally every kind of correspondence a company produces. This would also drastically cut setup time on the printing line, especially for large automated document factory’s that deal with countless different jobs every day. Every new order means reprogramming the systems to keep the forms coming from the right tray. Not an issue with white paper production.

White paper production is hardly a new idea. What is new is how hot the topic has become. More and more companies are taking a closer look at this type of output management. And it's no wonder: the savings potential is huge. Experts estimate savings of up to 80%.

The volume of hard-copy documents is shrinking worldwide in any case. Surveys by the Universal Postal Union (UPU) cite an average of seven percent. All in all, the ratio of electronic mail to physical mail is shifting. For at least the next two generations, however, both types will be used equally.