DocBridge® provides high-performance, platform-independent and scalable software solutions for Omnichannel Customer Communications and document management.

- Experts for Omnichannel Document and Output Management

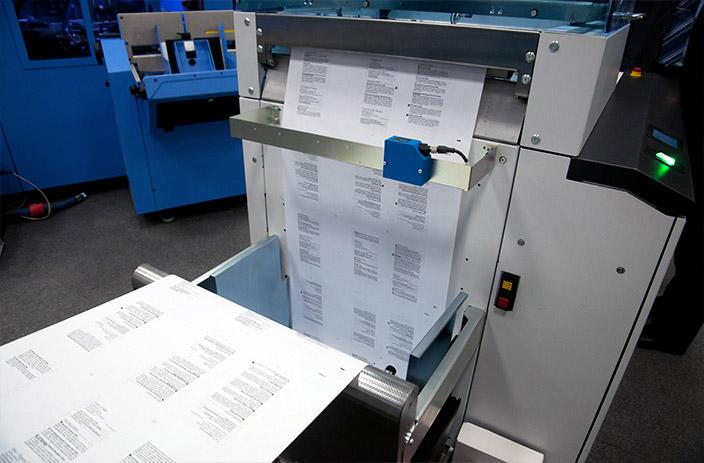

- Bridge between the analog and digital document world

- Digital first: state of the art document generation focused on electronic communication

- Proven expertise in quality assurance, document conversion and mail bundling/postage optimization

- Wealth of technology and consulting know-how for batch and individual processing

Headquartered in Germany, the company has been a market presence for 30 years, with subsidiaries and a network of partners in Europe, Africa, and North and Latin America.

Compart helps businesses create, produce and distribute documents using applications for compliant and efficient processing of large volumes of data in batch as well as transaction processes.

The DocBridge® product family that Compart develops, sells and supports covers the document and output management process from start to finish: creation, preparation, and output of information on every physical and electronic channel.

The company enjoys a reputation as a trendsetter worldwide. More than 1,500+ customers from a wide range of industries in over 50 countries (including banks, insurance companies, energy suppliers, telecommunications companies, print service providers, public administrations, logistics, and healthcare) use Compart applications.